What Are Digital Twins and How Are They Used in Product Testing?

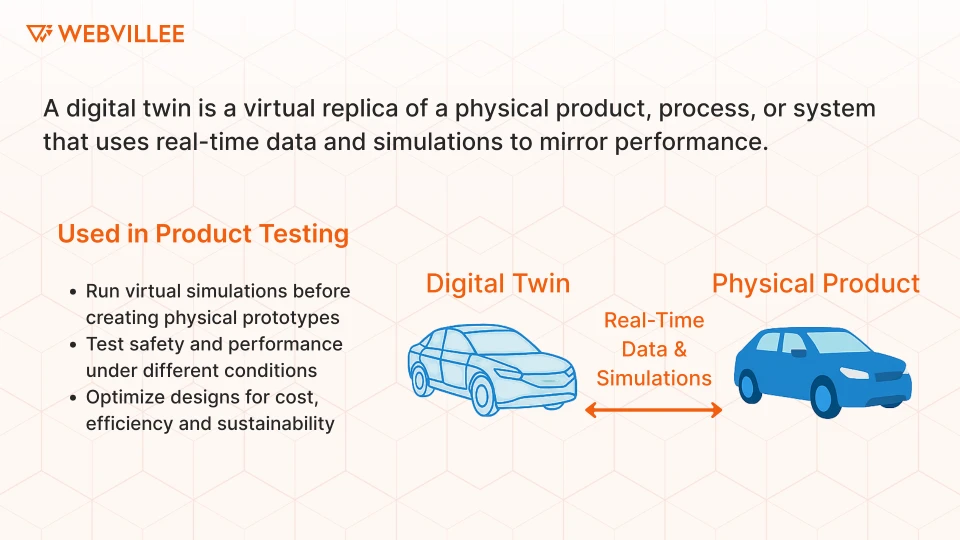

A digital twin is a virtual replica of a product or system that is used in product testing to simulate performance, reduce costs, and improve safety. Digital Twins in Product Testing allow businesses to experiment with designs and processes before physical models are built, helping them avoid costly mistakes and speed up development.

Digital twins work by combining real-time data, sensors, and simulation tools to create an accurate digital version of a product. This replica can then be tested under various conditions without physical risk. For businesses, this means higher efficiency, better product reliability, and smarter decision-making.

With the growing demand for cloud solution platforms and connected systems, digital twins are becoming essential in industries like automotive, aerospace, healthcare, and consumer products. In this blog, we will cover 9 practical use cases that demonstrate how digital twins improve testing across cost, safety, performance, and sustainability.

Key Takeaways at a Glance

Digital twins make product testing faster, safer, and more efficient across industries. Here are 9 practical use cases this blog will explore:

- Reducing Prototype Costs – Cutting down on multiple physical prototypes.

- Improving Product Safety Testing – Simulating hazardous conditions safely.

- Performance Optimization – Predicting failures and improving efficiency.

- IoT-Enabled Product Testing – Creating feedback loops with connected devices.

- Software Testing – Simulating real user environments before launch.

- Scaling Manufacturing Tests – Modeling entire production lines.

- Sustainability Testing – Designing eco-friendly, energy-efficient products.

- Supply Chain Testing – Predicting disruptions and optimizing logistics.

- Customer Experience Testing – Testing usability and personalization.

These use cases highlight the benefits of digital twins in driving smarter, cost-effective, and reliable testing methods.

How Do Digital Twins Reduce Prototype Costs?

Reducing Prototype Costs is one of the most common applications of digital twins. Instead of building multiple physical prototypes, companies can run simulations with digital replicas. This reduces material waste, lowers expenses, and speeds up development.

Examples include:

- Automotive crash testing, where virtual models predict results before a physical vehicle is built.

- Consumer electronics, where simulations help refine designs before investing in production.

By using digital replicas, businesses can reduce prototyping costs with digital twins and improve product quality earlier in the development cycle. This approach is a strong example of how Product Engineering benefits from digital twins in product testing.

Can Digital Twins Improve Product Safety Testing?

Improving Product Safety Testing is another area where digital twins provide value. By simulating hazardous conditions virtually, companies can test how products respond without risking people or assets.

Examples include:

- Aerospace engineering, where digital models are used to test aircraft under extreme conditions.

- Heavy equipment manufacturing, where stress tests are run digitally before physical use.

Digital twins for product safety not only reduce risk but also help businesses meet compliance and safety regulations. This aligns with larger Digital Transformation goals, where safety and efficiency are built into every stage of testing.

How Do Digital Twins Enable Performance Optimization?

Performance Optimization becomes achievable with digital twins because they analyze real-time data and predict failures before they occur. This leads to better product reliability and reduced downtime.

Key examples include:

- Predictive maintenance, where equipment health is monitored continuously.

- Performance benchmarking, where usage patterns guide improvements.

With performance optimization using digital twins, companies can make real-time adjustments that improve efficiency and customer satisfaction. Partnering with Managed IT Services helps organizations scale these models across systems, making digital twins in product testing even more powerful.

What Role Do Digital Twins Play in IoT-Enabled Products?

IoT-Enabled Product Testing is strengthened through digital twins, as they create feedback loops between connected devices and their digital replicas. This ensures products are tested and improved continuously.

Examples include:

- Smart home devices, where usage data informs product updates.

- Connected vehicles, where performance can be simulated before release.

Digital twins in IoT help companies build smarter, adaptive products. By integrating with Simplified IoT Solutions, organizations can ensure continuous monitoring, updates, and improved product reliability.

How Can Digital Twins Improve Software Testing?

Software Testing is enhanced through digital twins by simulating real-world user environments before deployment. This helps identify bugs early and improve user experience.

Examples include:

- Testing mobile applications against virtual replicas of devices.

- Simulating customer workflows before software goes live.

Software testing with digital twins ensures fewer deployment risks and better customer satisfaction. Businesses that invest in Java Development can combine these practices to deliver reliable, high-performing software. This makes digital twins in product testing a strong advantage in competitive markets.

Do Digital Twins Help in Scaling Manufacturing Tests?

Scaling Manufacturing Tests becomes easier with digital twins because they simulate entire production lines and workflows. This allows companies to detect inefficiencies before they affect operations.

Applications include:

- Detecting bottlenecks in assembly processes.

- Improving throughput by testing production at scale.

Digital twins in manufacturing tests also ensure better quality control. By combining simulations with SAP Services, businesses can optimize supply chains, maintain consistent quality, and reduce downtime in production.

Can Digital Twins Support Sustainability Testing?

Sustainability Testing is supported by digital twins by evaluating eco-friendly designs virtually before they are physically created. This ensures that businesses can focus on energy efficiency and waste reduction.

Examples include:

- Testing energy-efficient materials in construction or electronics.

- Measuring waste reduction in production cycles.

Sustainable product testing with digital twins allows companies to meet regulatory requirements and customer expectations. Leveraging Salesforce Services can help organizations align sustainability goals with operational data, strengthening their digital transformation journey. This makes digital twins in product testing an essential part of green innovation.

How Do Digital Twins Improve Supply Chain Testing?

Supply Chain Testing benefits from digital twins by modeling logistics systems and predicting potential disruptions. This makes planning more accurate and delivery more reliable.

Examples include:

- Inventory planning, where demand fluctuations are simulated to avoid shortages.

- Delivery optimization, where route planning is tested virtually.

Supply chain testing with digital twins helps businesses minimize risk and maintain smooth operations. Integrating these models with Service Now systems strengthens end-to-end supply chain visibility.

Can Digital Twins Improve Customer Experience Testing?

Customer Experience Testing is improved with digital twins because products can be evaluated from the end-user perspective before launch. This ensures higher satisfaction and better engagement.

Examples include:

- Personalized features, where customer behavior is simulated digitally.

- Usability testing, where interface designs are evaluated virtually.

Customer experience testing with digital twins allows companies to reduce churn and improve loyalty. Combining these practices with CRM & ERP platforms ensures that digital twins in product testing deliver insights that directly enhance customer value.

How Can Businesses Start Using Digital Twins for Product Testing?

Businesses can start using digital twins by identifying their use cases, selecting the right platforms, and integrating IoT and simulation data. These steps make it easier to implement virtual replicas effectively.

The benefits include cost reduction, safer testing, performance optimization, and stronger customer experiences. By adopting digital twins for product testing, companies can stay competitive and achieve faster innovation cycles.

For decision makers looking to explore tailored strategies, Webvillee offers expertise in cloud, product engineering, and enterprise technology. Get in Touch to learn how digital twins can transform your testing and product development approach.