How to Scale Your IoT Project from Pilot to Enterprise Production Without Derailing Budget

Moving an IoT pilot to production requires strategic planning around architecture, integration, and cost management. This guide shows enterprise leaders how to scale IoT projects successfully while keeping budgets in check.

Why Do Most Enterprise IoT Pilots Never Reach Production?

Most enterprise IoT pilots fail at scaling because organizations prioritize proof of concept over production readiness, leaving no clear pathway from working prototype to operational deployment.

The gap between a successful pilot and a production system is vast. A pilot proves technology works in controlled conditions. Production demands reliability, security, integration, and cost management across your entire operation.

Organizations often celebrate pilot results without planning the infrastructure jump required next. This disconnect causes projects to stall, waste budget, and delay the competitive advantages that IoT pilot to production systems deliver.

The cost of inaction grows quickly. Competitors who move IoT from pilot to production gain months of operational advantage, cost reduction, and data insights your business is missing.

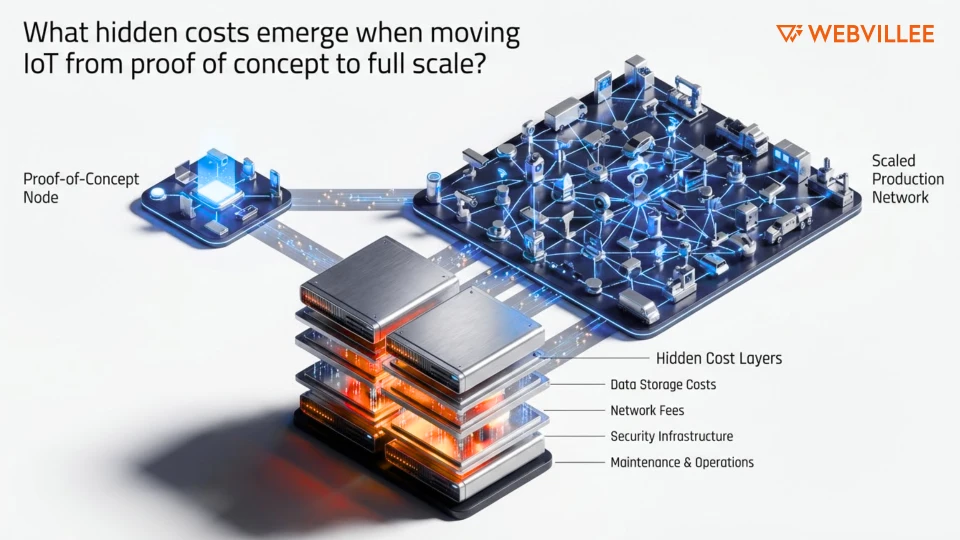

What Hidden Costs Emerge When Moving IoT from Proof of Concept to Full Scale?

Scaling IoT from proof of concept to production reveals three cost categories pilots don’t expose: infrastructure expansion, integration complexity, and operational overhead.

Moving beyond pilot requires investment most organizations underestimate. Budget failures happen when organizations assume pilot costs scale linearly. They don’t. Production costs typically 3-5 times pilot investment.

- Infrastructure costs multiply when connecting hundreds or thousands of devices instead of dozens. Edge computing, data storage, and cloud resources scale nonlinearly with device count.

- Integration expenses spike when IoT data must connect to your ERP, CRM, and operational systems. Pilots often skip this; production demands it.

- Operational staffing increases significantly. Monitoring, maintenance, troubleshooting, and data governance require dedicated expertise pilots don’t need.

- Security and compliance investment rises as your attack surface expands. What was acceptable in a pilot becomes a regulatory and operational liability in production.

- Change management costs emerge when training teams, updating workflows, and managing organizational resistance to new systems.

How Does Delayed IoT Deployment Impact Your Competitive Position?

Every month your IoT project stays in pilot, competitors with production systems gain operational efficiency, cost advantages, and customer insights you can’t match.

In manufacturing, competitors moving faster automate processes you still manage manually. In logistics, they track shipments and optimize routes while you rely on legacy systems.

The compounding effect of delay is severe. Competitors accumulate months of operational data your systems haven’t captured yet. They identify and fix production problems your pilots haven’t encountered. They build competitive moats through automation and efficiency gains you’re still planning.

Time is not your friend in IoT. The longer your project sits in pilot, the harder it becomes to justify continued investment, and the greater the risk executives lose faith in the initiative.

What Architecture Decisions Determine IoT Success in Enterprise Environments?

Production IoT success depends on upfront decisions about data flow, security, and system integration that pilots can defer but enterprises cannot.

| Pilot Approach | Production Reality |

|---|---|

| Test with handful of devices | Scale to hundreds or thousands |

| Store data locally or in test cloud | Route data through secure, audited infrastructure |

| Loose integration with existing systems | Seamless connection to ERP, CRM, analytics platforms |

| Basic authentication | Enterprise security, encryption, access controls |

| Manual data handling | Automated governance and compliance workflows |

The architecture question isn’t technical. It’s business: How will IoT data flow to the systems where decisions happen? Your Simplified IoT solutions need to connect seamlessly with your operational core. Data sitting in isolated IoT platforms creates no business value.

Edge computing decisions matter too. Do you process data at the device level, in local gateways, or in cloud systems? Each choice affects cost, latency, and operational control.

Which Integration Gaps Prevent IoT Data from Flowing into Your Existing Systems?

The Real Problem: Isolated IoT Data

IoT fails at scale when sensor data cannot flow automatically into your ERP, CRM, and operational systems where business decisions actually happen.

Why Integration Matters More in Production

Pilots often treat IoT as a standalone project. Production demands integration everywhere. When inventory sensors can’t update your ERP automatically, your procurement team still plans inventory manually.

And when equipment sensors don’t trigger maintenance alerts in your operational systems, technicians miss critical issues. When customer IoT data doesn’t reach your CRM, your sales team has no context for customer conversations.

The Cost of Gaps

Manual data transfers between systems create delays, errors, and duplication. Your teams waste hours extracting data from IoT platforms, transforming it, and loading it into business systems.

Integration complexity is why production fails. Pilots skip it. Enterprise deployments cannot.

How Do You Manage Security and Compliance Risks Without Slowing IoT Deployment?

Security and compliance cannot be afterthoughts in production IoT. Building them into your deployment plan from the start reduces risk, accelerates deployment, and prevents costly rework.

Pilots often operate with minimal security because they’re limited in scope. Production systems handle sensitive data, operate critical infrastructure, and must meet regulatory requirements.

IoT security challenges expand in production. Thousands of connected devices become attack targets if not properly secured. Data in transit requires encryption and authentication protocols pilots skip. Data at rest must meet compliance standards for your industry, whether healthcare, finance, manufacturing, or retail. Access controls need accountability for who accesses IoT data and when.

Compliance penalties for IoT failures are severe. Data breaches, unencrypted customer information, or unauthorized access can trigger regulatory fines, customer lawsuits, and operational disruptions.

The mistake is treating security as a separate phase. It must be integrated into architecture decisions upfront, not bolted on later.

What Measurable Business Outcomes Should You Expect from Enterprise IoT?

Production IoT delivers quantifiable returns through reduced downtime, lower operational costs, faster decision-making, and new revenue opportunities that pilots demonstrate but production realizes.

- Reduced operational downtime through predictive maintenance that catches failures before they stop production.

- Lower maintenance and energy costs by optimizing equipment operation based on real-time data instead of schedules.

- Faster response to operational problems because your teams see issues when they emerge, not days later through reports.

- Better inventory management by tracking stock movement in real time, reducing overstock and stockouts.

- New revenue opportunities by offering customers data-driven services or insights competitors cannot.

- Improved product quality through sensors that catch defects during production rather than after customer delivery.

These outcomes don’t materialize in pilots. They require production scale, proper integration, and teams trained to act on IoT insights.

How Should Your Organization Prepare to Make IoT Production Successful?

IoT production success requires more than technology: you need clear governance, skilled teams, stakeholder alignment, and change management planning from day one.

Technical capability is necessary but insufficient. Organizations that move pilots to production successfully address four critical areas.

- Build internal capability. Do you have teams with the skills to operate, maintain, and optimize IoT systems? Training and hiring decisions must start before production launch.

- Define governance and ownership. Who owns IoT data? Who approves how it’s used? Which teams act on IoT insights? Without clear governance, adoption stalls.

- Align stakeholders across functions. IoT affects operations, IT, finance, and business leaders differently. Early alignment prevents conflicts and ensures support.

- Plan change management. Your teams will resist new systems and workflows. Change management, training, and early wins build momentum and adoption.

These decisions determine whether production IoT becomes standard practice or gets abandoned when initial enthusiasm fades.

Next Steps

The path from pilot to production is clear but requires planning. Success depends on understanding costs, making architecture decisions upfront, securing stakeholder alignment, and building internal capability before scaling.

Contact Webvillee to explore how enterprises have moved IoT from pilot to production successfully. Schedule a consultation to discuss your specific requirements and timeline.